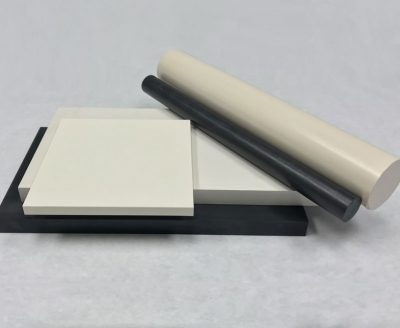

PPS Rods and Plates

Polyphenylene sulfide (PPS) is suitable for high performance structural components requiring thermal stability, structural integrity, high dimensional stability and exceptional resistance to a broad range of acids, alkalis, ketones and hydrocarbons.

PPS Rods and Plates

Polyphenylene sulfide (PPS) is suitable for high performance structural components requiring thermal stability, structural integrity, high dimensional stability and exceptional resistance to a broad range of acids, alkalis, ketones and hydrocarbons.

PPS is inert to steam, compatible with common sterilization methods, and can be machined to tight tolerances. It is inherently flame retardant with a high limiting oxygen index (LOI) and very low water absorption.

Key Features

Typical Applications

Our extruded STOCK SHAPES of the following grades provide a wide range of performance options for demanding applications:

Recommended products

Thermoplastic Polyimide (TPI)

Polyetheretherketone (PEEK)